Wooden railways are so much more than a children’s toy – they represent an extraordinary entry point for model railroading. Wooden trains and track emerged commercially in 1936 with incremental improvements in the mid-50s and the early-90s. Despite polluting encroachment of plastics and trains with prepackaged personalities, wooden trains remain an unequaled foundation for creative and cooperative play.

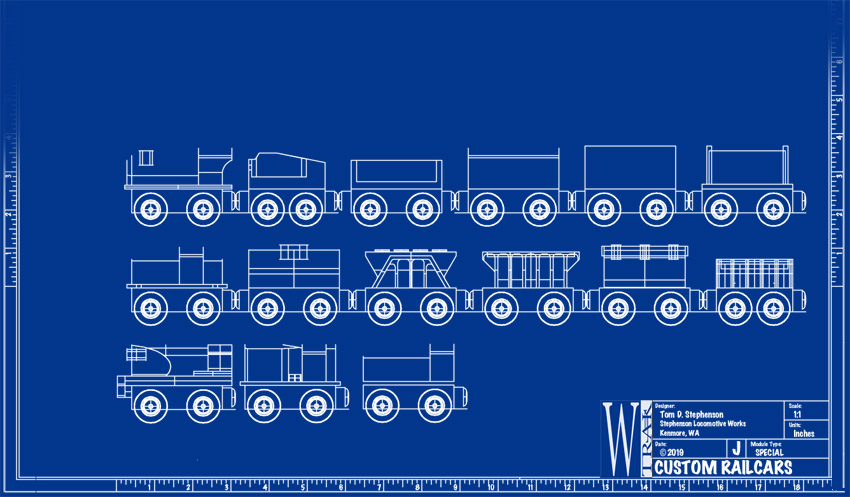

CNC provides a framework to design, share and manufacture custom track and rolling stock in imaginative ways – no longer constrained by catalogs from Brio, Thomas and others. Wooden railways with sidings, yards, interlaced turnouts, and elevated lines provide a foundation for learning how railroads are designed and operated. Designed to be open-source, there are links, diagrams and CNC files available to foster creativity and improve accessibility for hobbyists. Individual track pieces, tile railway systems and modular shelf or table railways – learning through design and play.

Brio and Thomas track systems are generally described as compatible. Connector geometry is common and the two systems have a consistent rail slot spacing, so layouts can be constructed using a mix of track from both. Of the two, Thomas introduced the most innovative designs (‘clickety clack track’ is arguably the best wooden track design commercially produced) while Brio has the most coherent fit and function (with parallel turnouts, 45° crossings and exceptional engineering design.)

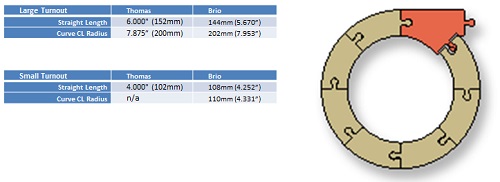

Brio is metric-based, with a 3mm rail slot. Thomas is inch-based, with a rail slot width of 1/8in. A small gap at connectors allows for a bit of angularity and length mismatch. In a sprawling layout with many pieces, misalignment is easily absorbed. That mismatch becomes much more problematic in a compact railway footprint.

The large turnout (switch) combines a large curve and a straight track section and is a good comparative element between the two systems. With a common radius and similar length (a 1% and 5% difference between systems respectively) they are essentially interchangeable. The small turnout is more difficult to compare because the Thomas series employs a modified turnout radius that differs from even its own small curve – a constant source of aggravation…

Pieces with parallel tracks are another benchmark within the two systems. Brio’s parallel straights and parallel curves are based on a nominal 46mm (1.810”) spacing between adjacent track centerlines – halfway between the large and small curve radius difference – allowing all variations to be connected in series. The Thomas series lacks a parallel curve and has no coherent centerline spacing – with three variations, many pieces cannot be connected in series.

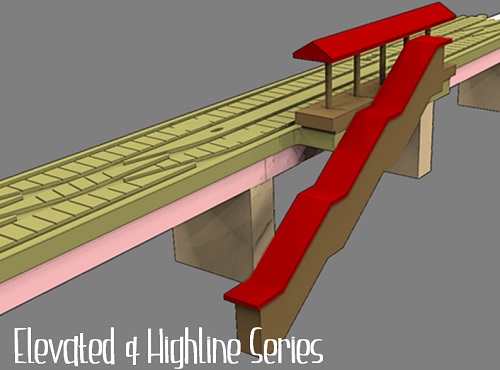

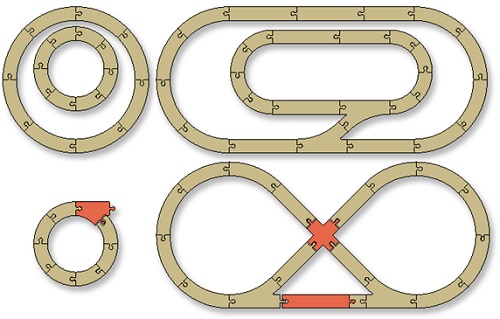

Circular, rectangular and figure eight layouts are easily configured with either system or a mix of the two. Parallel sidings and interior/exterior loops can be added using branching turnouts. Bridges and other elements can be substituted into straight segments to add visual complexity and elevation. Layouts from one point to another can also be made by simply extending the various branches of the layout. Railway elements from any combination of commercial wooden track sets can be used to create the layouts described above.

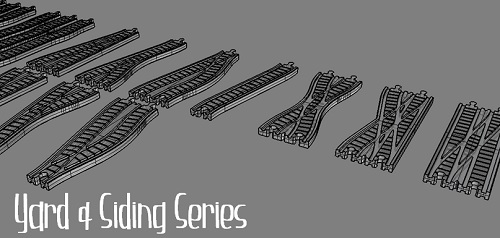

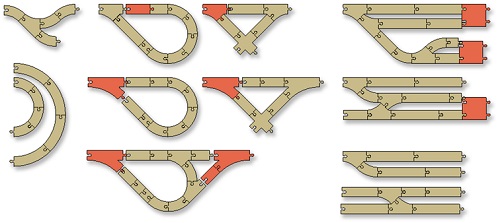

Yards and Sidings are fundamental elements in a railway. These are typically constructed using branching turnouts, parallel turnouts, angled crossings, parallel crossovers, and intersecting curves. Many of these pieces are part of the Brio system, though some are no longer available. Even fewer are found in the Thomas series. Due to differences in track series geometry (Brio .v. Thomas), inconsistent parallel track spacing (Thomas), limited track elements (Thomas), retired track elements (Brio and Thomas) and poor ‘system’ design (Thomas), constructing a typical yard or siding is surprisingly difficult to achieve.

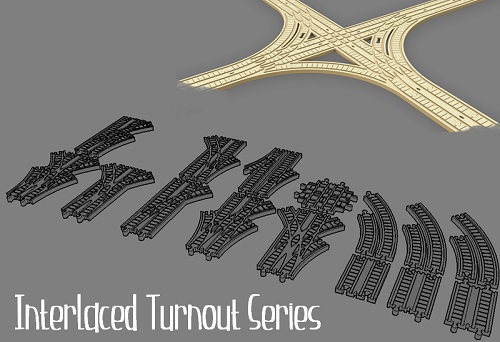

Models are mostly complete for several new series - 'Yards & Sidings', 'Elevated Rail', 'Interlaced Turnouts', 'Tile Railways' and 'Floor Modules' to share soon. Bookmark this page for updates throughout the Summer of 2020.